The Viking Fibreline series of caravans was based on the Africaravans Gypsey, which in turn had been developed with the help of Thomson caravans of Scotland. The following is an article from Caravanews (published by Africaravans) in October 1964, giving a brief history of the Gypsey. (The article and accompanying images have been copied from here, a website full of useful information on classic caravanning)

WHEREVER YOU GO WITH A GYPSEY CARAVAN, YOU WILL BE COMFORTABLY AT HOMEIn the primitive places of Africa is to be found much of great and unique interest. Because accommodation is not available, few people ever visit what still remains of "darkest Africa" South of the Limpopo. Those who own GYPSEY Caravans DO go exploring at every opportunity ... and they do it in style. They literally GO FIRST CLASS. So can you!

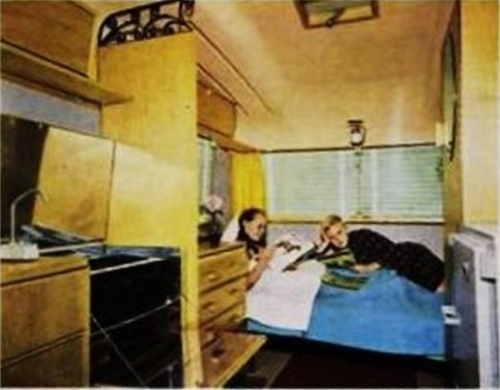

GYPSEY UNITY Fiberline is bright and airy. This large double bed is at one end. This model is a roomy home for four. You are cordially invited to visit our Garden Show-place to see the models on display. There are 5 GYPSEYs and a variety of models. At least one is bound to meet your needs. See them soon.

AFRICACARAVANS LTD PO BOX 115, PINETOWN, NATAL, with branches at

Bloemfontein, Johannesburg (Pretoria Road and Denver), King William's Town, Port Elizabeth, Belville and Pinetown.

A MESSAGE FROM THE CHAIRMAN

INTRODUCTION TO 10 YEARS OF PROGRESS

When the Chairman and Managing Director decided in 1954 that he must find another industry suitable to South Africa and something that would have a market value of all round benefit to the country and to intended buyers, his first step was to advertise in the newspapers throughout Europe and Great Britain.

He instructed Messrs John Palmer & Sons of London to place a suitable advertisement "calling for any manufacturers who considered he had something of value that might be manufactured in South Africa to make application and that capital would be made available." Replies came from hundreds of manufacturers, but the choice came to Caravans because subsequent investigations revealed that as the road programs of South Africa developed on a black top basis there would be a considerable opening and scope for Caravans.

All possible snags foreseeable were investigated and near destruction tests carried out. The results of the preliminary investigations pointed to the venture having a sporting chance of success.

The further researches have proved that caravans are undoubtedly of benefit to the country and the caravanning way of life has been taken up in a big way. The necessity has been a great success economically

Now you have the story in illustrated form of our factory.

THE SECOND STEP

The successful applicant was Messrs Thomson (Carron) Limited, caravan manufacturers, and the Company proceeded on the basis of purchasing four prototype caravans from them for the purpose of a caravan test throughout South Africa. Mr David Thomson the Managing Director of Thomson (Carron) Limited was appointed a Director of the Company.

The production and Technical Engineer was Mr T Doherty who was loaned to us initially by the Thomson (Carron) unit of Falkirk, Scotland, since when he has been Production and Technical Manager, developing the caravans to the stage that they have reached to-day.

Along with the idea of getting knowledge behind the organisation, plans were made for discussion with the owner of Andre Caravan & Trailer Co (Pty) Ltd, and in due course the Company acquired the Andre Caravan set-up, and Mr Andres himself was appointed as Sales Manager in 1956.

A FEW FACTS

The actual covered space on our 11 acre site at Headquarters is 44,295 square feet, including the working factory space, outbuildings and other amenities.

Throughout the country we have five District Manager's houses, seven selling sites, and five caravan parks. Total acreage is 52.2 acres (Pinetown 11, Pretoria 2.6, Johannesburg 21, King Williams Town 6.1, Bloemfontein 3.5, Cape Town 8).

It has been the Company's Policy to improve Caravans and Caravan service in all ways, and to take all possible action to improve the amenities throughout the country for caravan owners, using the medium of CARAVANEWS, owned by us.

DISPATCH

This is part of the factory you would not normally see, and the photographer had to scramble up on top of another building to take the picture. Here are GYPSEYs waiting to be sent to places all over South Africa, and the ones you see here were part of a special order for the Post and Telegraph Department.

When you order your new GYPSEY it pauses here for a few moments while it is checked to see that everything is in order. After that it goes to the department for private delivery if you are going to collect it from Pinetown, or starts on its journey anywhere from Cape Town to Bloemfontein.

FACTORY EXTENSIONThis is the Gypsey factory itself, showing the extension that had to be built very soon after the factory was opened because of the enormous demand for GYPSEYs. Here you can see part of the 44,290 square feet of covered space which has become necessary to give you full service.

And now we will take you inside the factory itself.

In the furniture department, skilled cabinet makers design and produce the furniture that goes into your GYPSEY. Much of it is made from expensive imported plywoods, which ensure the necessary lightness and give durability to GYPSEY interiors.

Many original Gypseys are still on the road doing brilliant service . They were based on a design which originated in Scotland. This caravan was chosen as the prototype for the 'Gypsey' as it had many features which made it the most suitable that could be found for use in South africa. At that time, eight years ago, a team of expert builders came out to Pinetown to transform the original caravan into the vehicle of which we hoped you would be proud to own, and the foresight of the design staff and the builders proved to be right.

The latest GYPSEYs are designed to a specification that has been largely dictated by you. This is the caravan that thousands of customers say they want. The chassis and bodywork is strong, infinitely durable, and pretty to look at. While inside their layout gives you all the comfort you have asked for. And all the GYPSEYs built at Pinetown have hydraulic and overrun brakes for your safety.

------------------------------------

The Africaravan company was sold to Caravans International Ltd (CI) in 1964. The following year, the former board of directors of Africaravan created Viking Fibreline Caravans and set up their factory at Glencairn Mill in Heads Nook, near Carlisle. There now follows an introductory article by The Caravan magazine in December 1965, copied from

The Thomson T-Line History website.

The next article, copied from the same source as above, is from The Caravan Magazine dated June 1966, and gives more detail on this initial model.

The December 1965 edition of The Caravan carried this advert.

This magazine cutting (also copied from the

Thomson History site), featuring the 1967 Viking model, describes the changes made for the second year of production.

When attempting to date a Viking Fibreline, the only sure way is to read the plate affixed to the A-frame. This had stamped on it the production number, date of production and its 'ex-works' weight. If this plate is missing or has deteriorated to the point of being illegible, then you can only guess. However, there are tell-tale clues to narrow down a guess. Components sometimes have their manufacture date on them, so the caravan would be dated later (e.g. on our 1970 Viking, the coupling hitch has 1969 in the casting, and the Labcraft ceiling light was labelled August 1969). Otherwise, it is down to recognising the changes made by Viking throughout the production period. It should be borne in mind they did not make these changes on the 1st January, so where I state certain details relate to a year of manufacture, Viking could have started using these details late in the year before, or at any point during the stated year. As an example, there were a number of changes made for the 1973 model year, but I know of several examples with these features where the owners say they are dated '72. To make things even more complicated, there are likely to be anomalies where the last of old stock was being used up before the new design features were fitted; this was a common practice in the automotive world so I see no reason why caravan manufacturers would be different. Finally, Viking caravans were hand made, allowing variations in locations of doors, windows and interior fittings. There are no official records remaining and therefore this article is based on my own observations and the accuracy, or otherwise, of other owners' information.

The magazine articles reproduced above give plenty of information for identifying the first two year's models. The 1966 version, which commenced in the latter half of 1965, had unpainted, stucco (dimpled) aluminium body panels below the waistline, a Rubery Owen chassis with a B&B Beta III hitch and four stud wheels. Three models were available, the MkI (10ft 9in), MkII (12ft 8in) and MkIII (14ft 4in). The toilet compartment was a £15 option.

These pictures show a '66, production number 118, before and after its conversion into a mobile bar. The bare aluminium had been painted green by a former owner.

For 1967, the whole outside was painted, the body was 2 inches lower and the end windows made deeper. Wheel arch spats were added and the toilet compartment came as standard. Wheels are now five stud so perhaps this was when Viking changed to using chassis by Peak Trailers. Three lengths were still available, with the largest now being 14ft 6in.

This image is of a '67 model (number 211), on which 5 stud wheels can be seen.

As far as I can tell, Viking made no changes for 1968. The photo below of a '68 model (number 271) shows Vikings still had the narrow raised section of roof (The interior picture of a separate caravan illustrates the lack of headroom in the toilet compartment because of this style of roof). Also visible is the Herzim trim along the middle of each side being at the same height as the trim at the ends, the corner windows extend down almost to the level of the trim, the grab handles were still fitted at an angle, and the upper vents on the sides were located in the roof, above the gutter/awning rail. There was an alternative position for the vents, just below the gutter (see the photo of a '69, below). Apparently, the doors were one piece as opposed to the two piece stable doors fitted later.

It was during 1969 that the next changes were made. The most noticeable was making the raised section of the roof wider, to allow more headroom inside. Additionally, the centre side trims are higher and no longer line up with the end trims. The gap between the trim and the bottom of the corner windows became larger. The grab handles were fitted horizontally, and were standardised into the steel tube and cast brackets arrangement that was fitted to all future models. The upper vents at the sides became stamped louvres in the aluminium panels, just below the upper trim line. The door became a two-part stable door. The two pictures below are both said to be '69 models by their respective owners, showing these changes happened at some time that year. In the photo of the earlier version, we can clearly see the hitch is one from Peak Trailers, confirming they were definitely using these chassis by then. More of the later model can be viewed

here, including a few interior shots.

Having made considerable changes in '69, Viking continued with this styling through 1970. Our Viking was completed in February 1970 and is number 440. By then, they were also moulding triangles for reflectors onto the rear of the lower body. This advert is from the March 1970 edition of 'The Caravan' magazine.

I have not yet mentioned interiors or gas boxes. It seems buyers could choose from a range of options and layouts for the kitchen regarding fridges and ovens, and the wood frame for the kitchen was designed to be assembled in a number of different configurations. Over the years, it has been fitted in a range of locations too. Couple this with it being common for owners to make their own changes, and it becomes difficult to date Vikings by their interiors. The only feature I can mention are handles fitted to cupboards and drawers; the earliest models had almost V-shaped handles, changing in 1969 to the bow shaped handles present in our Viking, then at some point in the 70s (I haven't worked out when due to a lack of available information), they fitted a latch with finger-pull ring to cupboards and an L-shaped handle to drawers.

Earliest Vikings appear to have not had gas boxes, the bottles just being clamped to the A-frame. The 'bread bin' style of gas box (shown in the advert above) was initially an option (confirmed in the 1973 brochure further down this page). The problem for this gas box was the size of gas bottles. It was designed around the Calor gas bottle, that being the only supplier of LPG at the time. However, in 1970, Flogas started to supply gas but their bottles are taller and will not fit these boxes. Many owners seem to have fitted alternatives, either from other caravans or aftermarket sources, until Viking started making larger boxes later in the decade.

1971 also brought no changes. Serial number 702 was produced this year, but the chassis plate does not say which month.

The following image is said to be a '71 model. The front marker lights are different, but this could have been an owner modification, or it could have been Viking using the new style lights mentioned in the next paragraph.

During 1972, for the 73 model year, there were a number of new features introduced by Viking. Most noticeably, they stopped fitting the rear corner windows, leaving just the curved aluminium panel. (There is a comment on a Viking Facebook group from someone who worked at the Viking factory. He said there was only one employee who could fit these windows. Personally, I find this hard to believe, and think it's more likely they were deleted either for cost reasons or because they fall out too frequently.) Other changes were the front corner windows became deeper, extending down to the belt line. The front marker lights were changed to round, domed ones. A number plate moulding was added to the rear valence. Drop back vents were included in the tops of the side and rear windows. The upper vents changed position to the panel between the upper trim line and the gutter, and all vents became holes in the side covered with a rectangular louvred panel. A vent was added to the bottom of the lower half of the door. The wheels changed to four-stud fitting. Additional to the existing three body sizes, by now there was also a 'Companion' model available. This was based on the largest 14ft 6in body, but had a door on each side and included many optional extras as standard. This image is of a '72 Companion.

Having made so many changes, things were left unchanged for 1973. These images are of Viking number 748, completed in January 1973, and illustrate many of the new features (plus a home-made spare wheel mount).

This brochure is for the 1973/74 range. Note the comment on the last page confirming the A-frame fairing and gas box were still optional extras.

1974 also brought hardly any amendments as big changes were about to appear in '75. This photo is said to be of a '74.

|

| Brochure excerpt copied from a sale advert for a '74 model |

This picture shows the rear of what I suspect to be a late '74 model, and one of the last to have aluminium panels front and rear. Ignoring the aftermarket trailer lights, what can be seen is a new moulding of the rear valence with an almost full width recess, and deeper recesses for the reflectors. This moulding remained in use until production ceased in 1980.

1975 saw the biggest changes to the Viking styling. Out went the aluminium body panels at the front and rear, and in came new fibreglass mouldings, fitted between the roof section and bottom section. The corner windows were no more. Cleverly, Viking used the same moulding at both ends, simply cutting out different window apertures, and installing circular red reflectors on the rear where the domed marker lights would be at the front. The central side trim was lowered to line up with the moulded line at each end but, bizarrely, the split in the stable door remained higher up. This is despite a new door mould (top half at least) as the door top became horizontal; it had sloped on previous models. New cranked door hinges replaced the former cast hinges, and the exterior handle changed to a rectangle shape. On the inside, the most noticeable change was to the upper shelves at the front and back, which were boxed in to form cupboards.

This advert is for the 1975 range, but the Earls Court show was in November (presumably 1974) and pictures the new fibreglass ends but old style door hinges. The caravan was therefore either a prototype just to showcase the new panels, or, as suggested much earlier, they were using up old stock of hinges before changing to the new style. Also evident in the image are glass windows with drop back vent, and a door with sloped top but new style handle. It also shows they were still supplying the 'bread bin' gas box at this time.

At the time of writing, I have not yet been able to find out when Viking changed from glass windows to plastic ones. An expert on Facebook said it was 1976, but I am yet to verify that, and will edit this post once I do. I can see from images on the internet that some Vikings were fitted with plastic windows with drop back vents at the top.

A detail of note on the price list dated September 1978 is the name of the company. All prior documents have shown the manufacturer's name as Viking Fibreline Caravans, but here they have become a limited company. At no time was the business ever called 'Viking Rendezvous Tours', although there are a couple of entries on the internet that would say otherwise.

Viking seem to have supplied at least three different gas boxes in the last five years of production. They are all larger than the original, to house bigger gas bottles. The following brochures show two of the styles, and the picture of the June 1980 model at the bottom displays the third type.

This document for a trade show is likely to have been printed in September 1979. Unfortunately, the photographer cut off the publication date but the specification list says prices remain firm until January 1980, and based on a price list from 1978 above saying the same, I feel my guess at the date is reasonable.

This picture of an occupier's handbook has a production number written on it, showing Viking number 1151 came off the production line in January 1980.

This photo is from an old for sale advert. The seller stated the production date was 30th June 1980.

My apologies for the lack of detail in the last five years of production. The exterior barely changed and there is little information available on the internet. As I confirm more information, I will of course amend this article.

Viking caravans ceased production in 1980. There is a discussion amongst two former employees on a Facebook page, saying the company had been in financial trouble since '75. Looking at the production numbers (only 400 caravans in the final seven years averages at just over 1 built per week), it's not difficult to see why. They also mention the fibreglass moulds being destroyed when the company stopped trading. There is a rumour the moulds went to Australia but as they were not subsequently used, I feel the story of destruction is more likely.

The history of Viking Fibreline Caravans Ltd production ends there. Their products have lasted much longer than the company did, which is a testament to the design of the caravans, the quality of materials used, and the care with which they were built. There was an owners' club but it has long since disbanded, and now there remains just a couple of Facebook groups dedicated to this brand (Classic Viking Caravans and Viking Fibreline Community), plus the enthusiasts who have kept these unique caravans in use.